Product

Mid-speed ZGM series Vertical Mill

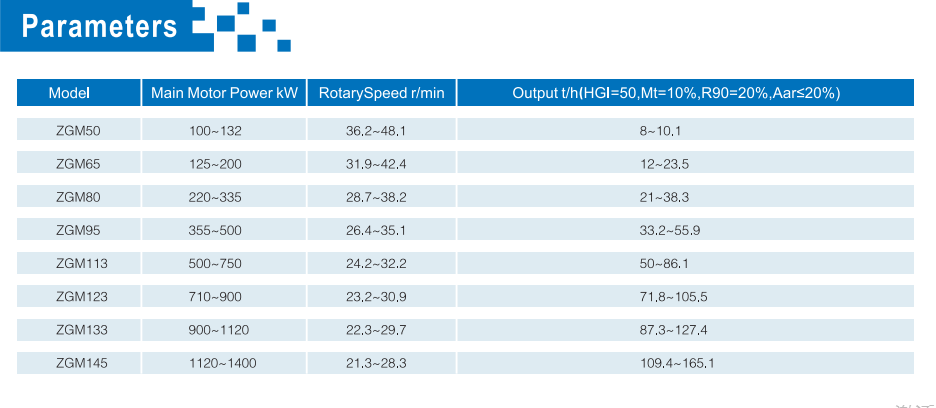

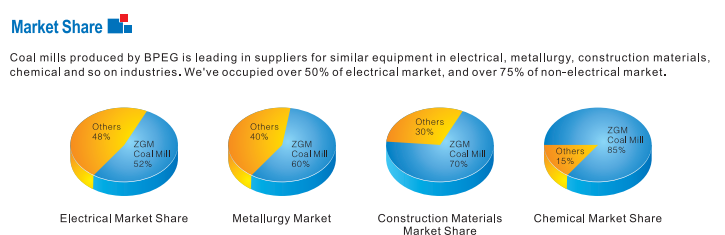

Beijing Power Equipment Group Co., Ltd. (BPEG) produced the first domestic 151 bowl-type mid-speed coal mill in 1958. To date BPEG has become the biggest mid-speed roller coal mill manufacturer both at home and abroad. ZGM series coal mills include 8 models and 73 specifications, having the strengths of wide applicability to different coal types (including soft coal, anthracite, brown coal, meager lean coal, etc.), high pulverizing efficiency, low power consumption, long operating life, reliable performance, and convenient maintenance. Currently they're widely applied to coal powder preparation systems in electrical, metallurgy, building materials, and chemical industries.

Additional to strong producing capability of coal mills, BPEG has also accomplished independent designing and manufacturing of its auxiliary equipment including vertical planetary gearbox, high starting torque motor, electronic weighing belt coal feeder, lubrication unit, hydraulic unit, slide gate, and the control system. Therefore, we're devoted to providing customers with complete solutions and services to pulverizing systems.

-

Outstanding Output

The three rollers of the ZGM coal mill are arranged with 120° angle between one and another. They adjust the grinding pressure regarding different coal types, and have the advantages of big roller diameter, low grinding table rotary speed, little grinding resistance, and great grinding-in conditions, all resulting in improving the output. Utilization of differentiation mould lines design has the advantages of high grinding efficiency. Especially in later period of service life, it still guarantees stable output, with maximum decrease less than 5%.

- Low Power Consumption

Advanced variable hydraulic loading technology enables automatic adjustment of grinding roller loading force according to the output arrangement. It ensures stable operation in underload conditions without unusual vibration. On the premise of continuous safe operation, the minimum output of each coal mill can be adjusted to 25% of maximum output, which is remarkably economical.

- Wide Coal Powder Fineness Adjustment Range

Application of rotary classifier effectively lowers the resistance, and improves the coal powder fineness (R90510%), which enables sufficient coal combustion so as to meet environment protective emission requirements.

- Long Service Life of Wear-Resistant Parts

Based on traditional high-chromium iron and build-up welding wear-resistant parts, we have developed the new ceramic composite material, which prolongs the service life of wear-resistant parts, especially for coal with high abrasion index.

- High Stability

The loading pressure is transfered by the gearbox to the base, while the static system transfers the loading pressure evenly. The housing of the coal mill is relieved from pressure, therefore even under high loading force, the coal mill still operates stably.

- Convenient Maintenance

According to the site conditions, two options are available: rotary of rollers, and parallel shift of classifier.

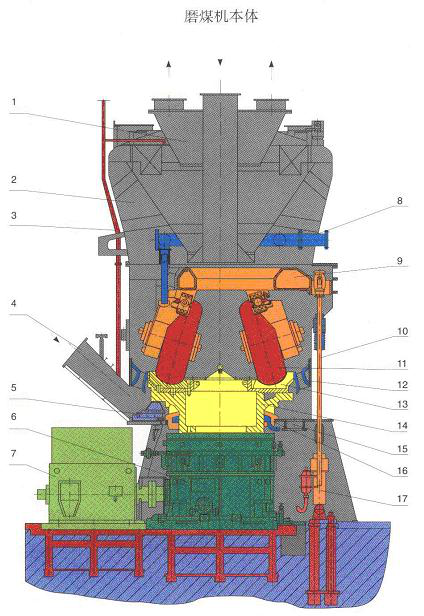

The body of ZGM coal mill is composed of engine base, housing, classifier, reduction box, spray head, milling device (Millstone and three rollers), hydraulic pressure loading device, pulverized coal distributor box, seal device, slag discharging unit, vapor explosion-proof device, basic platen and footpath and so on. The main matching devices arelubrication unit, hydraulic unit, seal fan, electric motor and electric control cabinet and so on.

1.Pulverized Coal Distributor Box 2.Classifier 3.Explosion-proof Vapor Pipeline 4.Hot Wind Entrance 5.Strike-off Board Group 6.Reduction Box 7.Electric Motor 8.Seal Wind Pipeline 9.Press Frame 10.Bar 11.Grinding Roller 12.Spray Head 13.Millstone 14.Driving Disc 15.Slag Discharging pole 16.Seal Hoop 17.Loading Cylinder and Energy Storage